Troubleshooting Custom Professional Socks Problems

Nowadays, personalization is becoming increasingly popular. Whether in business or in daily life, more and more people prefer unique designs. Therefore, customized socks provide unlimited possibilities for everyone. However, there are some technical and production issues with customizing socks, so there may be some communication and other problems in actual customization.

一. Main Problems with Custom Socks

1.Higher Prices

The price of custom socks primarily depends on the craftsmanship involved and the quantity ordered. Different customization techniques come with varying production costs. For instance, if you’re looking to create custom non-slip socks, a one-time fee is required for creating a non-slip logo template. During the manufacturing process, a significant amount of silicone liquid must be heated and fixed onto the bottom of the socks. Attaching and detaching the mold to the machine also takes time, adding to the overall production time.

On the other hand, embroidered socks involve a different process. First, a template for the embroidered logo must be created. Then, threads of the corresponding colors are loaded onto the embroidery machines one by one. The actual embroidery process is carried out on over 20 machines simultaneously, which means the preparation time is quite lengthy. Since the costs for these molds and templates vary, the overall production costs differ accordingly.

When it comes to quantity, the initial setup time remains the same regardless of how many pairs you order. However, ordering in smaller quantities can lead to more material waste and reduce the total output per machine each day. This is because the setup time and fixed costs are spread across fewer items, making each pair more expensive.

2.Longer Delivery Times

Since each pair of socks is customized according to the customer’s specific requirements, production time is naturally extended.

The total time is divided into production time + confirmation time + shipping time.Our samples will take 3-5 days to complete. After that, we will wait for the customer to confirm whether the design and quality of the socks meet their expectations. Once confirmed, we will proceed with bulk production. Producing 5,000 pairs will take approximately 20-25 days. Shipping will be handled by DHL, UPS, or FedEx, and the typical delivery time is 5-7 days.Of course, the specific time depends on the quantity. If you need urgent production, you can also let us know and we will arrange according to the order situation.It is recommended that customers plan ahead, especially before holidays or special occasions.

3.Design Limitations

When it comes to customizing socks, it’s important to understand that different production techniques come with certain limitations. These limitations are due to the technical constraints of the machinery used in the manufacturing process. Here are a couple of examples to illustrate these constraints:

1.Knitted Logo Colors:

One common limitation is with knitted logos. Our machines can only support up to 6 different colors per row. This is because the machinery is designed to handle a maximum of 6 colored yarns at a time. If your design requires more than 6 colors in a single row, it may need to be adjusted to fit within this technical limit.

2.Logo Serrated Edge:

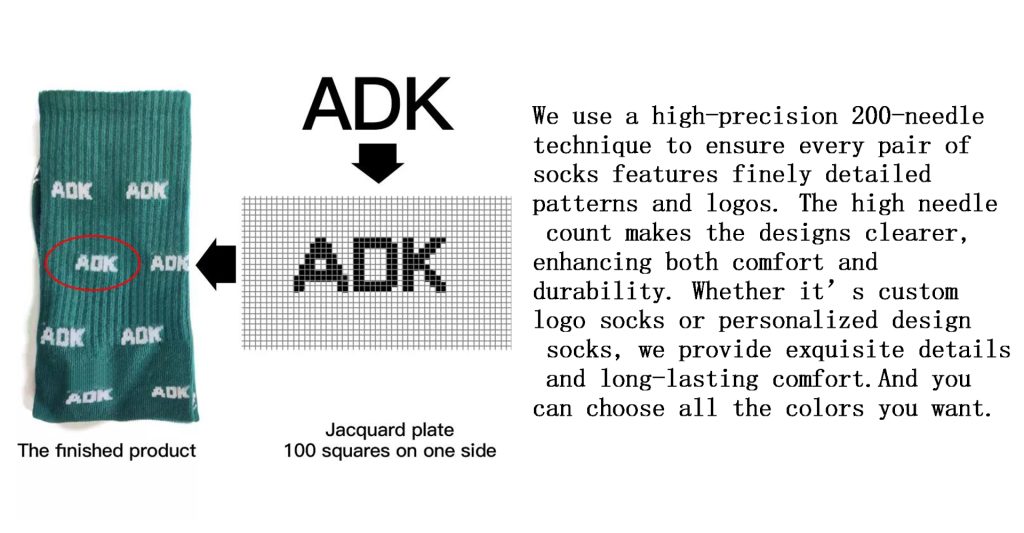

Socks with knitted logos may have some jagged edges at the edges of the logo. This is because knitting is done one stitch at a time, so the logo is pixelated, resulting in jagged edges. The method to make the sawtooth shape smaller is to increase the logo pixels and increase the number of stitches. Conventional knitting machines use 144N, 168N, 200N, and 200N to achieve better results than 144N.

So the sock factory needs to receive the logo first, and based on the type of logo, we will recommend suitable craftsmanship to ensure maximum effect. If there is a target process but the logo is not compatible, we have professional designers who can simplify the logo to achieve maximum effect.

4.Size and Fit Problem

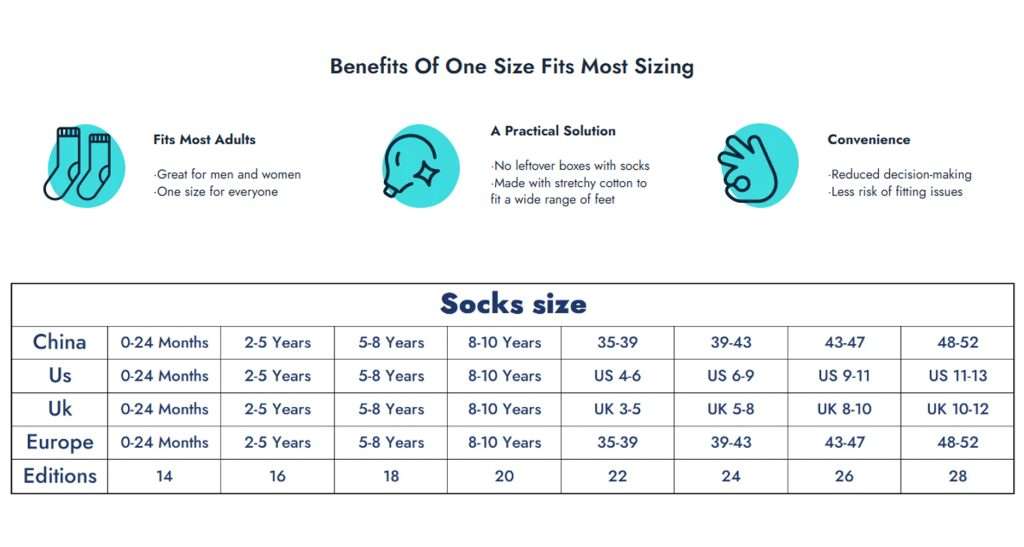

Different countries and brands may have different size standards, which may result in socks that do not fit properly, are too small or too large, and affect wearing and walking. So there may be doubts about the dimensions produced by the factory. Some customers may not know what size they actually need, which can cause frustration. You can check how to measure the size of your feet in ‘Custom Socks Knit To Fit Your Feet’.

The size of Europe and America is relatively larger compared to Asia. We have been providing high-quality customized services for countries such as the United States, the United Kingdom, Canada, and Australia for a long time. The sizes we produce fully comply with local standards, so we have compiled a size chart for different countries.

5.Color and Material Discrepancies

Due to variations in lighting, angles, and monitor settings, the colors you see on your screen may differ from the actual product. This discrepancy may lead to customers receiving products that do not meet their expectations.

We have taken photos of Socks yarn colors, and you can choose them directly online, or you can send us the colors you need. We will find the most suitable yarn for production. At the same time, customers can purchase our color swatches, which will enable better customization of different colors.

二.Other Challenges in Customer Experience

Customers may not be familiar with the entire process of customizing socks and may not know how to get started. In fact, customers only need to inform the factory of their requirements, and the factory will provide some corresponding solutions based on your needs. You just need the solution you like. At the same time, it is necessary to confirm all the contents of the order, such as production date, whether packaging is included, and whether tariffs are included(When importing goods, import tariffs from the target country must be paid),Reduce subsequent issues.

Return and Exchange Policies The return and exchange policies for custom products are usually quite strict because each item is made according to the customer’s specific requirements. This may be unsatisfactory for some customers, especially when the product has issues. It is recommended that customers carefully check the design before customizing and retain the order confirmation information for communication purposes if needed.

三.How Businesses Can Improve

Set up professional customization software for customers who have the need to design their own socks. They can adjust the color of various parts of the socks, add logos, adjust the size and color of logos, and the logo format can be different formats of images and text. This way, customers can design socks according to their own ideas and reduce inconvenience caused by communication. After the design is completed, you can download the file and send it to the factory.

Many customers are not aware of what the cost should include, so some factories initially quote a very low price, and after paying the order, they will incur a lot of additional costs. So our website indicates all items included in the cost, and there are no other expenses.

If you are not familiar with the techniques for customizing socks, you can check out our “Sock Styles” page, which includes pictures and advantages of different techniques. Clicking on the picture will also provide a detailed introduction to the techniques. In short, customizing socks is not difficult. The main thing is to choose a responsible and high-quality factory. We hope you can find a sock factory that meets your standards.

Of course, you can try contacting us. We have been in the sock industry for over 20 years, providing high-quality customized sock services to over 3000 customers. We have a complete customized sock process and have received multiple positive reviews from our customers